Search

SCHWING Stetter, MAX-truder Tie-up to Deliver Precast Concrete Solutions

The companies aim to create positive economic value and pave the way for modular construction in India.

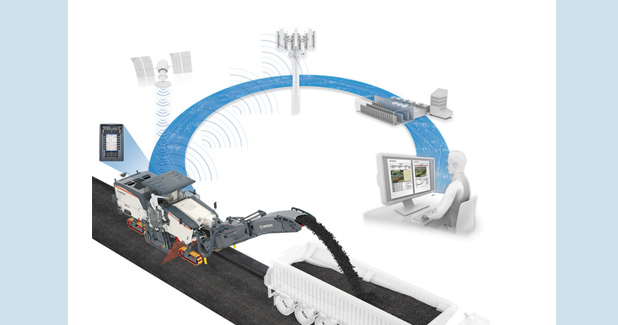

Smart Automation in Roadbuilding

Smart Automation in Roadbuilding stands for precise asphalt reclamation and paving along paths defined by digital terrain models.

Wirtgen to Unveil 45 Innovations at bauma 2025

The Wirtgen Group and John Deere will showcase advanced construction equipment, technology solutions, and application processes at bauma 2025 in Munich.

Schwing Stetter Exhibits Eco-friendly CE at Bharat Mobility

Schwing Stetter marked a significant milestone in contributing to the Nation’s 2070 net-zero goal

Schwing Stetter honoured by Leadership Management International

Schwing Stetter India, one of the country’s leading construction and concreting equipment manufacturer, was recently honoured as the “World Client of the Year†at a conference held by Leadership Management® International (LMI), a world leader in organisational and leadership development.

Schwing Stetter honoured by Leadership Management International

The company has been honoured with "World Client of the Year"

What new construction equipment will 2022 bring?

The outlook on India’s construction equipment sector is optimistic since the country’s needs for infrastructure will continue to grow massively.

Wirtgen turning 60 – A driver of innovation with rich history

Construction machinery from Windhagen is in use all over the world today. In addition to Wirtgen cold milling machines, which are found on virtually every road rehabilitation job site, the machine manufacturer also produces technologically leading recyclers, soil stabilizers, slipform pavers, and surface miners.

Volvo CE introduces 3 new construction BEVs

Roads and highways sector is considered to be the most vibrant infrastructure segment where a lot of activities ongoing consistently for a long time.

Schwing Stetter India joins the fight against Covid-19

Schwing Stetter India, one of the largest manufacturers of concreting and construction equipment’s across the country, announced that it has converted a floor in one of its existing building of its factories – F75 unit in Sri Perumbadur into a Covid care centre.

YoY demand for concrete equipment will be at 20-25% in today’s scenario

Incorporated in June 1998, and commencing its manufacturing operations in 1999, Schwing Stetter India is a 100 per cent subsidiary of Schwing GmbH, a $1.30 billion German concreting machinery manufacturer and a part of XCMG group.

Wirtgen Group machines lead to motorway rehabilitation in record time

Contractor Johann Bunte Bauunternehmung showed how to rehabilitate the surface and binder courses of a section of a motorway successfully in an incredibly short time.

Road Equipment: Road to Recovery

The Ministry of Road Transport and Highways (MoRTH) has big plans of constructing expressways, national highways, state highways and rural roads in the coming years. However, any uncertain economic situation in future may affect the recovery of the market as this will affect the payment of contractors, financing and thus equipment mobilisation.

Solving Big Challenge

A W 210i and W 2100 precisely milled the spillway chute of the Oroville Dam, the highest dam in the USA. In this process, the milling contractor also benefited from cold milling specialist Wirtgen’s application experience in steep gradient milling.

Registration and driving licence not needed for road making machines: MoRTH

The Ministry of Road Transport and Highways (MoRTH) has clarified that the heavy road making machinery is not a motor vehicle, and is not covered under MV Act.

BETTER road rehabilitation WITH COLD MILLING

Cold milling is one of the first measures taken when a roadway or traffic area needs to be rehabilitated.

Performance tracker for milling work

Wirtgen has developed Performance Tracker, a solution that, for the first time, makes it possible to accurately and reliably document the actual milling work completed.

Wirtgen Group's Smart Synergies at bauma

The Wirtgen Group is showcasing its innovative road construction machinery among the company's around 120 exhibits and 13,000 sq m of exhibition space at bauma 2019.

Operator training is a necessity today

Wirtgen India revived its training school almost one-and-a-half years back to give training in its pavers range. Ramesh Palagiri, Managing Director & CEO, elaborates more on the company's views on skill development and the way forward.

New solutions in road construction

The focus of this year's Road Technology Days held by the Wirtgen, V?gele and HAMM brands was on synergies, 3D applications and networked job site processes. The climax of the event was the live machine demonstrations.

New technologies gaining traction

The Wirtgen Group has been continuously innovating its products in the brands Wirtgen, Vogele, and Hamm. They are not only global market leaders but also innovation leaders, with the average age of a machine being not more than three years.

We will be launching 17 new products this year

The current construction equipment market in India is to grow at a rate of 25 per cent. Road, irrigation, ports, RMC, railways, metro rail, power (nuclear, thermal, solar, wind, hydro, gas based), real estate and other community buildings are the major demand drivers for our product line.

Fulfilling the trenching needs

In Austria, a Wirtgen W 100 CFi compact milling machine with deep milling unit is being used for trenching prior to the laying of broadband cables - just before it sets to work milling off entire pavements.

Relying on Wirtgen's Cold Milling Range

Costello Industries relies exclusively on cold milling machines from Wirtgen.Costello Industries, Inc, a milling service provider based in Newington, CT, USA, has been rehabilitating highways, streets and bridges since 1945.

Machine control systems are the future in India

MOBA is a German company that provides automation solutions for moving machines. Speaking to EQUIPMENT INDIA, Samip Desai, National Manager, Moba Mobile Automation (I), explains the company's activities and solutions for the Indian market.

Making Faster and Safer Tracks

To make the 'Marco Simoncelli' Misano World Circuit faster and safer, Pesaresi Giuseppe SpA decided to take advantage of the cutting-edge technologies of Wirtgen and Trimble. In less than three weeks, all irregularities were removed from the track, leaving it ready for more spectacular motor sports competitions.

We would showcase innovations across all our four brands

With the infrastructure development polices of this government, there is good demand and growth for the CE industry. The difference from last bC India, is that two years back, the new government in place had ambitious plans to develop the road sector. Now the plans are being executed well, and due to this there is an increase in demand for equipment.

Asphalt Removal in Record-Breaking Time

Three Wirtgen cold milling machines (two W 210 and one W 200i) and two Wirtgen soil stabilisers (WR 2000) demonstrate their productivity and reliability at Alghero-Fertilia Airport in Sardinia.

Cold Milling Machines

Similar to developed nations, pavement milling or cold milling or cold planning of asphalt topped pavements is fast going to become a necessity in India, considering the volumes of crushed, screened, sized and shaped aggregates required for the upcoming roads and infrastructure projects, in the country.

Delivering Versatility

One of the first Wirtgen W 200 Hi cold milling machines is being used in Italy, where the large milling machine demonstrates its unique practical flexibility day after day, with a milling drum assembly that can be displaced 400 mm to either side.

First Kleemann Screen Rolled Out in India

Wirtgen India rolled out the first Kleemann range screen from the newly inaugurated plant, and is set to launch a slew of products for the Indian market.

Asphalt Recycling

Millions of tonnes of asphalt have being wasted in the country, when these could be properly treated and recycled for rehabilitation of road projects and new pavements.

Scope for pavement rehabilitation alternatives is huge

Our Ministry of Road Transport and Highways (MORTH) has no vision for the country. Cannot they spend even 0.01 per cent of the total outlay for training? This is simply unacceptable, says Prof. Prithvi Singh Kandhal, Associate Director Emeritus, National Center for Asphalt Technology, Auburn University, Alabama, USA.

Technology Mania!

Wirtgen Group recently organised 'The Road Technology Days 2014, an international industry rendezvous in Germany that showcased the Group's innovative solutions.

New HT22 quick-change toolholder system

Wirtgen New HT22 quick-change toolholder system for maximum milling performance and cost efficient operation. Cutting technology is a core competence of Wirtgen and the heart of its cold milling machine technology.

The new generation of Dash-3 pavers from Vogele will be launched at Excon 2013.

n addition to production, we are also focusing on optimising our process, improve efficiencies in operations and at the same time, stepping up investment in sales and service network for the future, says Ramesh Palagiri, Managing Director and CEO, Wirtgen India. Excerpts from the interview.

We offer intelligent compaction system for soil and asphalt compactors in India

We have moved the Dynapac technology and expertise from Europe to India for the benefit of Indian customers. We are now producing the 11 T class soil compactor CA250 and the 9 T class asphalt compactor CC384HF here in Nashik.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com